Ukwenziwa kwePVC

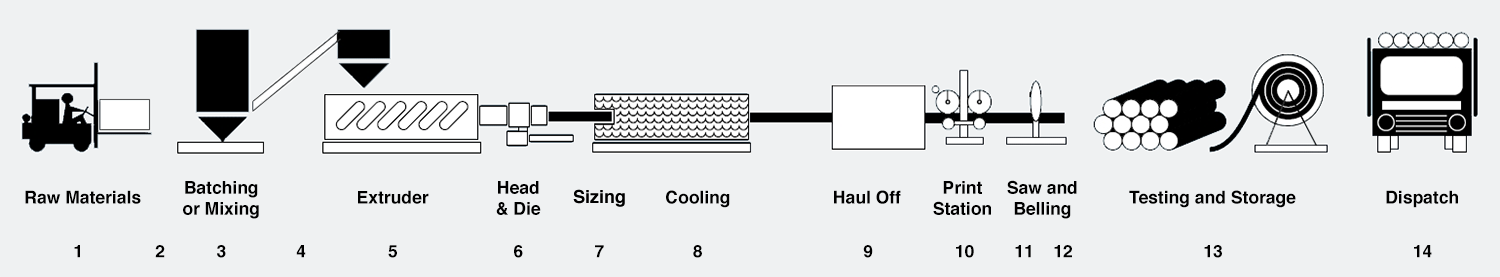

Ngokusisiseko, iimveliso zePVC zenziwe ngomgubo wePVC okrwada ngenkqubo yobushushu kunye noxinzelelo.Iinkqubo ezimbini eziphambili ezisetyenziselwa ukwenziwa zi-extrusion yombhobho kunye nenaliti yokubumba izifakelo.

Ukusetyenzwa kwePVC yanamhlanje kubandakanya iindlela eziphuhliswe kakhulu zenzululwazi ezifuna ulawulo oluchanekileyo kwiinkqubo eziguquguqukayo.Izinto ze-polymer ziyi-powder ejikelezayo yamahhala, efuna ukongezwa kwe-stabilizers kunye nezixhobo zokusebenza.Ukuqulunqwa kunye nokudibanisa ngamanqanaba abalulekileyo enkqubo kunye neenkcukacha eziqinileyo zigcinwa kwizinto ezingenayo ezingenayo, ukudibanisa kunye nokuxuba.Ukutya kwi-extrusion okanye kumatshini wokubumba unokuthe ngqo, ngendlela "yomxube owomileyo", okanye uqhutywe ngaphambili kwi-granular "compound".

Extrusion

Iipolymer kunye nezongezelelo (1) zilinganiswe ngokuchanekileyo (2) kwaye zicutshungulwa ngokuxutywa kwesantya esiphezulu (3) ukudibanisa izinto eziluhlaza zibe ngumxube odibeneyo osasazwa ngokufanayo.Ubushushu obuxutywayo obumalunga ne-120°C buphunyezwa bubushushu obukhukulisayo.Kumanqanaba ahlukeneyo enkqubo yokuxuba, izongezo ziyanyibilika kwaye ngokuthe ngcembe zigqume i-PVC polymer granules.Emva kokufikelela kwiqondo lokushisa elifunekayo, umxube ukhutshwa ngokuzenzekelayo kwigumbi lokupholisa elinciphisa ngokukhawuleza ubushushu ukuya kuma-50 ° C, ngaloo ndlela uvumela umxube ukuba uhanjiswe kwindawo yokugcina ephakathi (4) apho ubushushu kunye nokuxinana kweqondo kufezekiswa.

Intliziyo yenkqubo, i-extruder (5), ine-barrel elawulwa yiqondo lokushisa, i-zoned apho ukujikeleza ngokuchanekileyo "izikrini".Izikrufu zanamhlanje ze-extruder zizixhobo ezintsonkothileyo, ziyilwe ngononophelo kunye neenqwelomoya ezahlukeneyo ukulawula ukunyanzeliswa kunye nokucheba, eziphuhliswe kwizinto eziphathekayo, ngexesha lazo zonke izigaba zenkqubo.I-twin counter-roting screw configuration esetyenziswa ngabo bonke abavelisi abakhulu inika ukuphuculwa kokulungiswa.

I-dryblend ye-PVC ifakwe kwi-barrel kunye nezikrufu, ezithi ke ziguqule umxube owomileyo kwindawo efunekayo "yenyibilika", ngobushushu, uxinzelelo kunye nokucheba.Ngethuba lokuhamba kwayo kunye ne-screws, i-PVC idlula kwiindawo ezininzi ezicindezelayo, i-homogenise kwaye ikhuphe umlambo onyibilikayo.Ummandla wokugqibela unyusa uxinzelelo lokukhupha ukunyibilika ngentloko kunye nesethi yokufa (6) equlunqwe ngokobukhulu bombhobho ofunekayo kunye neempawu zokuhamba komjelo wokunyibilika.Nje ukuba umbhobho ushiye i-extrusion die, ulinganiswa ngokudlula kwi-sleeve yokulinganisa echanekileyo kunye ne-vacuum yangaphandle.Oku kwanele ukwenza lukhuni umaleko wangaphandle wePVC kwaye ubambe i-diameter yombhobho ngexesha lokupholisa kokugqibela kumagumbi okupholisa amanzi alawulwayo (8).

Umbhobho utsalwa ngokulinganisa kunye nemisebenzi yokupholisa ngumtsalali okanye ukukhupha (9) ngesantya esingaguqukiyo.Ukulawulwa kwesantya kubaluleke kakhulu xa esi sixhobo sisetyenziswa kuba isantya apho umbhobho utsalwa khona uya kuchaphazela ubukhulu bodonga lwemveliso egqityiweyo.Kwimeko yombhobho odityanisiweyo werabha ukutsalwa kwerabha kuyacotha ngamaxesha afanelekileyo ukujiya umbhobho kwindawo yesokethi.

Umshicileli we-in-line (10) uphawula imibhobho ngamaxesha aqhelekileyo, kunye nokuchongwa ngokobukhulu, iklasi, uhlobo, umhla, inombolo yoMgangatho, kunye nenombolo ye-extruder.Isarha yokusika ngokuzenzekelayo (11) inqumla umbhobho kubude obufunekayo.

Umatshini wentsimbi wenza i-socket ekupheleni kobude bombhobho ngamnye (12).Kukho iindlela ezimbini eziqhelekileyo zesokethi.Kuba umbhobho odityanisiweyo werabha, i-mandrel edibeneyo isetyenziswa, ngelixa i-mandrel ecacileyo isetyenziselwa i-solvent joint sockets.Umbhobho weringi werabha ufuna i-chamfer kwi-spigot, eyenziwa mhlawumbi kwisikhululo sokusarha okanye iyunithi yokubetha.

Imveliso egqityiweyo igcinwa kwiindawo zokubamba ukuze zihlolwe kunye novavanyo lokugqibela lwebhubhoratri kunye nokwamkelwa komgangatho (13).Yonke imveliso ivavanywa kwaye ihlolwe ngokuhambelana neMigangatho efanelekileyo yase-Australia kunye / okanye kwiinkcukacha zomthengi.

Emva kokuhlolwa kunye nokwamkelwa, umbhobho ugcinwa ukuze ulinde ukuthunyelwa kokugqibela (14).

Kwimibhobho ye-PVC (PVC-O) ejoliswe kuyo, inkqubo ye-extrusion ilandelwa yinkqubo eyongezelelweyo yokwandisa eyenzeka phantsi kweemeko ezichazwe kakuhle kunye nokulawulwa ngononophelo lobushushu kunye noxinzelelo.Kungethuba lokwandiswa apho i-molecular orientation, enika amandla aphezulu afana ne-PVC-O, yenzeke.

Isitofu sokubumba

Ufakelo lwePVC lwenziwa ngokubumba inaliti yoxinzelelo oluphezulu.Ngokwahlukileyo kwi-extrusion eqhubekayo, ukubumba yinkqubo ye-cyclic ephindaphindiweyo, apho "i-shot" yezinto eziphathekayo ihanjiswa kwi-mold kumjikelezo ngamnye.

Imathiriyeli yePVC, nokuba ikwimo yomxube owomileyo yomgubo okanye imo ekhompawundi yegranular, ngumxhuzulane otyiswa kwihopha ebekwe ngaphezulu kweyunithi yokutofa, ukuya kumphanda wendlu yesikrufu esibuyiselanayo.

Umgqomo uhlawuliswa inani elifunekayo leplastiki nge-screw ejikelezayo kunye nokuhambisa izinto phambi kombhobho.Isikhundla se-screw simiselwe "ubungakanani bokudubula" kwangaphambili.Ngethuba lesi senzo, uxinzelelo kunye nokushisa "iplastiki" izinto eziphathekayo, ngoku kwimeko yayo enyibilikayo, ilindele ukujova kwi-mold.

Konke oku kwenzeka ngexesha lomjikelo wokupholisa wokudubula kwangaphambili.Emva kwexesha elimisiweyo i-mold iya kuvula kwaye ukufakwa okubunjiweyo okugqityiweyo kuya kukhutshelwa ngaphandle.

Ukungunda emva koko kuvalwe kwaye iplastiki enyibilikisiweyo ephambi komphanda itofwe phantsi koxinzelelo oluphezulu ngesikrufu esisebenza njengeplunger.Iplastiki ingena kumngundo ukuze yenze ukufakwa okulandelayo.

Emva kwesitofu, ukutshaja kwakhona kuyaqala ngelixa ukufakela okubunjiweyo kuhamba kumjikelo wokupholisa.

Ixesha lokuposa: Jun-23-2022