Imathiriyeli ekrwada yokuvelisa imibhobho yePVC

Imathiriyeli ekrwada yokuvelisa imibhobho yePVC,

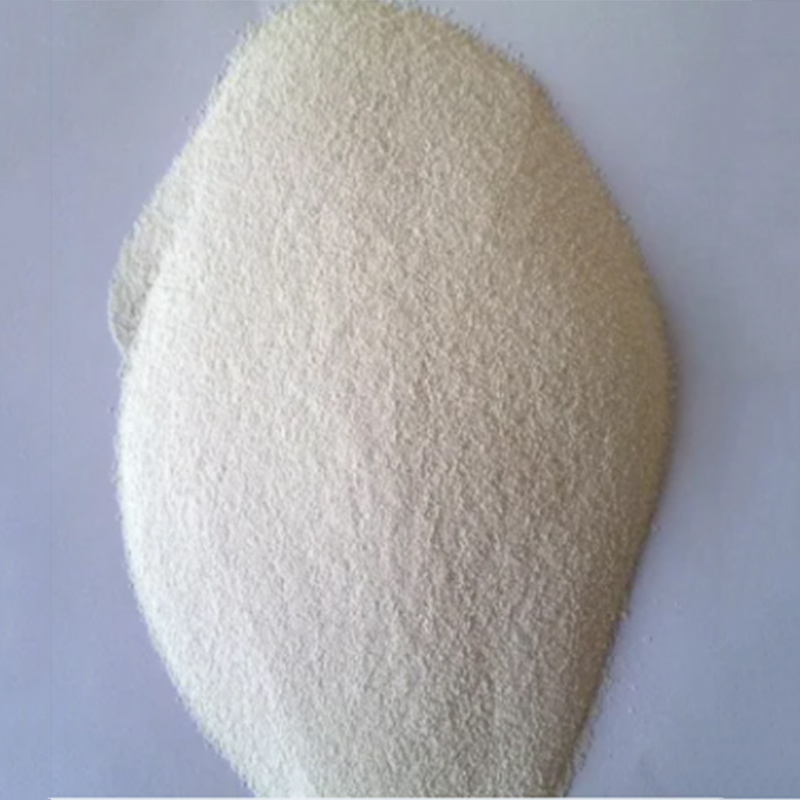

I-PVC Resin, PVC ukuvelisa umbhobho,

I-S-1000 i-polyvinyl chloride resin iveliswa yinkqubo yokumiswa kwepolymerization usebenzisa i-vinyl chloride monomer njengento ekrwada.Luhlobo lwekhompawundi yepolymer kunye noxinzelelo olunxulumene ne-1.35 ~ 1.40.Indawo yayo yokunyibilika imalunga ne-70 ~ 85℃.Uzinzo olubi lwe-thermal kunye nokumelana nokukhanya, ngaphezulu kwe-100 ℃ okanye ixesha elide phantsi kwelanga i-hydrogen chloride iqala ukubola, ukuveliswa kweplastiki kufuna ukongeza izizinzi.Imveliso kufuneka igcinwe kwindawo eyomileyo nengenamoya.Ngokomlinganiselo weplastiki, ukuthamba kweplastiki kunokulungiswa, kwaye i-resin yokunamathisela inokufumaneka nge-emulsion polymerization.

IBanga le-S-1000 lingasetyenziselwa ukuvelisa ifilimu ethambileyo, iishiti, isikhumba esenziwe ngumntu, imibhobho, ibha enemilo, umbhobho, imibhobho yokukhusela intambo, ifilimu yokupakisha, i-sole kunye nezinye iimpahla ezithambileyo.

Iiparamitha

| IBanga | I-PVC S-1000 | Amagqabantshintshi | ||

| Into | Ixabiso lesiqinisekiso | Indlela yokuvavanya | ||

| Isidanga somndilili wepolymerization | 970-1070 | GB/T 5761,Isihlomelo A | K ixabiso 65-67 | |

| Uxinaniso olubonakalayo, g/ml | 0.48-0.58 | Q/SH3055.77-2006, iSihlomelo B | ||

| Isiqulatho se-Volatiles (amanzi afakiwe), %, ≤ | 0.30 | Q/SH3055.77-2006, iSihlomelo C | ||

| Ukufunxwa kwePlastiki ye-100g resin, g, ≥ | 20 | Q/SH3055.77-2006, iSihlomelo D | ||

| Intsalela yeVCM, mg/kg ≤ | 5 | GB/T 4615-1987 | ||

| Uvavanyo % | 2.0 | 2.0 | Indlela yoku-1: GB/T 5761, iSihlomelo B Indlela yesi-2: Q/SH3055.77-2006, Isihlomelo A | |

| 95 | 95 | |||

| Inombolo yeFisheye, No./400cm2, ≤ | 20 | Q/SH3055.77-2006, iSihlomelo E | ||

| Inani leengqungquthela zokungcola, Hayi., ≤ | 16 | GB/T 9348-1988 | ||

| Ubumhlophe (160ºC, 10minutes kamva), %, ≥ | 78 | GB/T 15595-95 | ||

Imibhobho ye-PVC yenziwa ngokukhutshwa kwezinto ezikrwada zePVC, kwaye ngokubanzi ilandela amanyathelo afanayo okwenziwa kombhobho oqhelekileyo wokukhupha:

I-1.Ukutya komgubo ococekileyo obizwa ngokuba yi-resin kunye ne-filler kwi-PVC twin screw extruder;

2. Ukunyibilika kunye nokufudumeza kwiindawo ezininzi ze-extruder;

3. Ukukhutshwa kwidayisi ukumila kumbhobho;

4.Ukupholisa umbhobho owenziweyo (ngokutshiza amanzi kumbhobho);kwaye

5. Ukusika imibhobho yePVC ukuya kubude obufunwayo.

Iimathiriyeli ekrwada yokuvelisa imibhobho ye-PVC yiresin kunye nesithambiso (ikakhulu i-calcium carbonate, okanye eyaziwa ngokuba ngamatye).Umxube oqhelekileyo ngu-1 kilogram (kg) ye-resin kunye ne-1 kilogram yokuzalisa.Iinkqubo zemveliso zizenzekelayo, kunye nabasebenzi bondla izinto eziluhlaza ekuqaleni kwenkqubo, ukubeka iliso kwiqondo lokushisa kwinkqubo kunye nokujonga imveliso yokugqibela naziphi na iziphene ezicacileyo ngaphambi kokupakisha kunye nokuthunyelwa kubathengi.Bonke abasebenzi baqeqeshiwe kwaye bayakwazi ukwenza yonke le misebenzi ngokufanelekileyo.Eyona nto iphambili yokwenziwa kwemibhobho yePVC yinto engumgubo ebizwa ngokuba yiPVC resin.